Dear CNBTJSA customer,

After careful consideration, the CNBTJSA Board of Directors has determined that it is necessary to implement a change in our sewer usage rates to continue providing the high level of service that you have come to expect from us.

The decision to raise our rates has not been made lightly. Over the past three years, we have experienced increasing costs in materials, supplies, chemicals, and regulatory compliance. These costs are essential to ensure that we are treating the wastewater that we receive and protecting the natural resources of our community and the surrounding area. The plant is currently undergoing a $10 million dollar upgrade to secure a long-term treatment process that will allow us to continue to provide reliable, efficient treatment for years to come.

We last adjusted our rates in 2023 and again in 2025. In the past three years, we have seen substantial increases in our operating costs and have absorbed those increases as they have occurred. It is necessary for us, at this time, to raise our rates 9% in order to compensate for our higher operating costs due to the past several years of inflation. Based on the sewer usage of our average residential customer, this rate increase will result in an additional cost of approximately $4.00 per month. Obviously, usage and the subsequent sewer bills may vary based on individual households' water consumption.

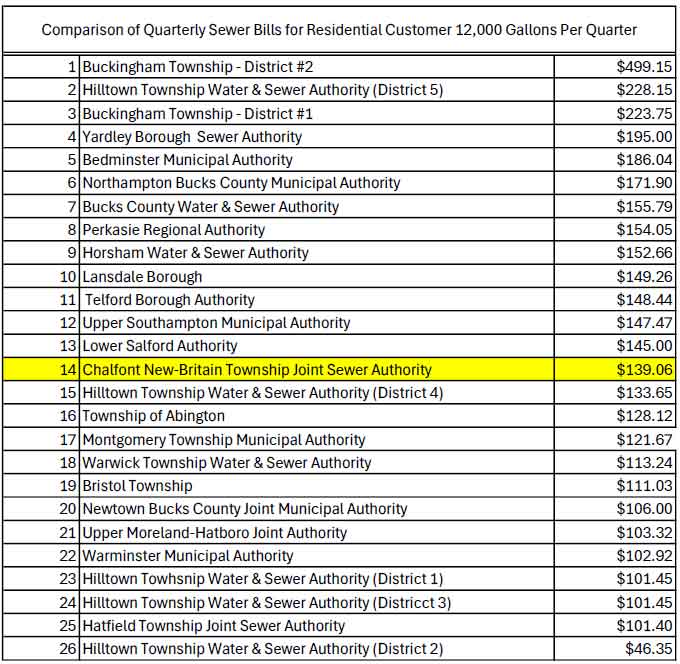

Even with this increase, the Authority believes that our sewer rates continue to provide exceptional value to our customers. The value of clean water cannot be overstated. As you can see in the table below, our rates are still below average for our region.

We understand that the price increase will be an inconvenience for our customers, and we want to assure you that we remain committed to providing the best possible service in the most cost-effective manner that we can.

Please click here for the new sewer rates.

Construction of Phase III of the Authority’s Treatment Plant Expansion and Upgrade Project, which began in May of 2016, is now complete. In conjunction with the Phase I and II projects, this project improves the treatment plant’s process capabilities, its operational and energy efficiencies, and provides major maintenance and replacements of various facilities in the plant to help ensure the long-term integrity of the treatment plant. LB Industries, of Hellertown, PA, was the General Contractor on the project, and BSI, Inc., of Montgomeryville, PA, was the Electrical Contractor. CKS Engineers, Inc., of Doylestown, provided engineering design and construction management. The total cost of the Phase III project was approximately $6.7 million. The combined cost of all 3 phases, which began in 2008, was about $19 million. Major items of improvement for the Phase III project include:

Please see the Plant Tour page of our website for further information on treatment process descriptions and photos.

Construction of Phase II of the Authority’s Plant Expansion and Upgrade Projects is now complete. In addition to other related projects, the completion of this project improves the treatment process capabilities, the operational and energy efficiencies, and has increased the facility’s rated treatment capacity from 4.0 million gallons per day to 4.625 million gallons per day, as average daily flow.

The total cost of the project was about $7.2 million. C&T Associates of Souderton, PA, was the General Contractor on the project, and Thomas Controls of East Brunswick, NJ, was the Electrical Contractor. Project design, construction management, and inspections were conducted by the Authority’s consulting engineer, CKS Engineering of Doylestown, PA.

Major items of improvement in this project included:

The Authority’s previous project, Phase I, was completed in May of 2010, at a total cost of $5.99 million. Improvements constructed as part of that project included: construction of a new 95-foot-diameter Final Clarifier tank with a peak flow capacity of 10 million gallons per day, and construction of a new Ultraviolet Disinfection System and building.

Please see the “Plant Tour” section of our website for further information on treatment process descriptions and photos.